AIRCRAFT FLUSH WASHING AND SURFACE TREATMENT FACILITIES

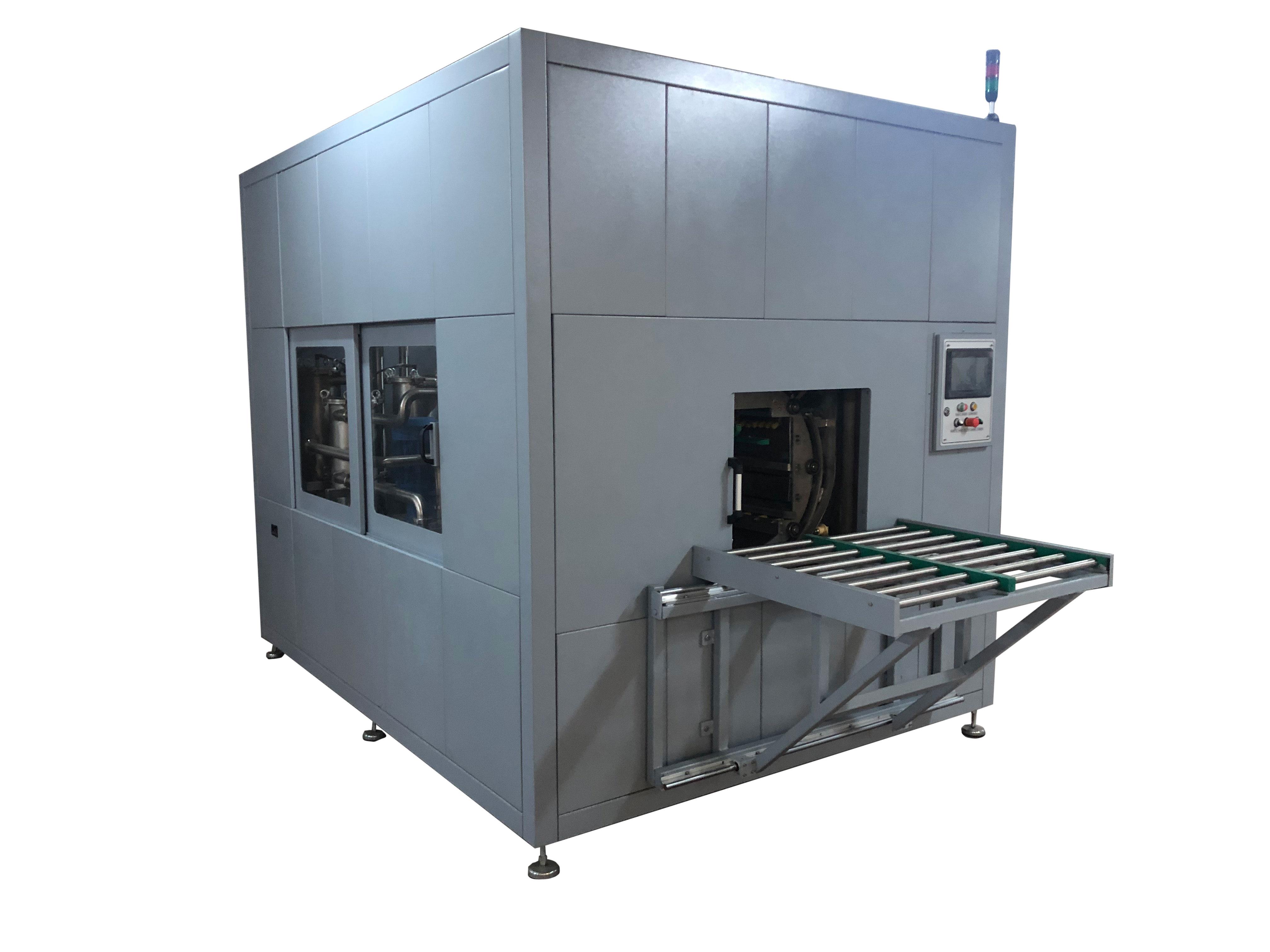

Automatic Washing Machines, basket or drum basket in a closed cabinet; These are the systems where washing process is performed by rotating at an angle in two directions.

The materials placed in the basket are loaded into the machine via the loading-unloading platform. Washing processes; It is carried out by spray and immersion washing.

Basket / Drum Basket movement is programmed as full turn, half turn and fixed. Right angled nozzles scan every point of the part effectively. By blowing air with a high flow fan, the water on the surface is removed with air, and vacuum drying enables the material to dry with hot air in a short time in a moisture-free environment.

Every point of the piece is effectively cleaned by spray washing and immersion washing.

After the washing and drying processes, the part is cooled with freckles.

Cleaning results at the desired level can be obtained in sensitive parts.

Advanced security levels and mobile robot applications such as Material Identification, automatic recipe selection according to the material are used.

Basket and drum Basket dimensions are selected according to the size of the piece to be processed. Special fixture and basket applications can be made according to the shape of the part. All operations are carried out in the same cabinet at times that can be adjusted by PLC control.

Some Application Areas

Aircraft engine block body, aircraft engine parts, block covers washing,

Washing Aircraft Engine Shafts,

While washing aircraft engine discs,

Washing for all kinds of aluminum alloys, titanium and iron alloys,