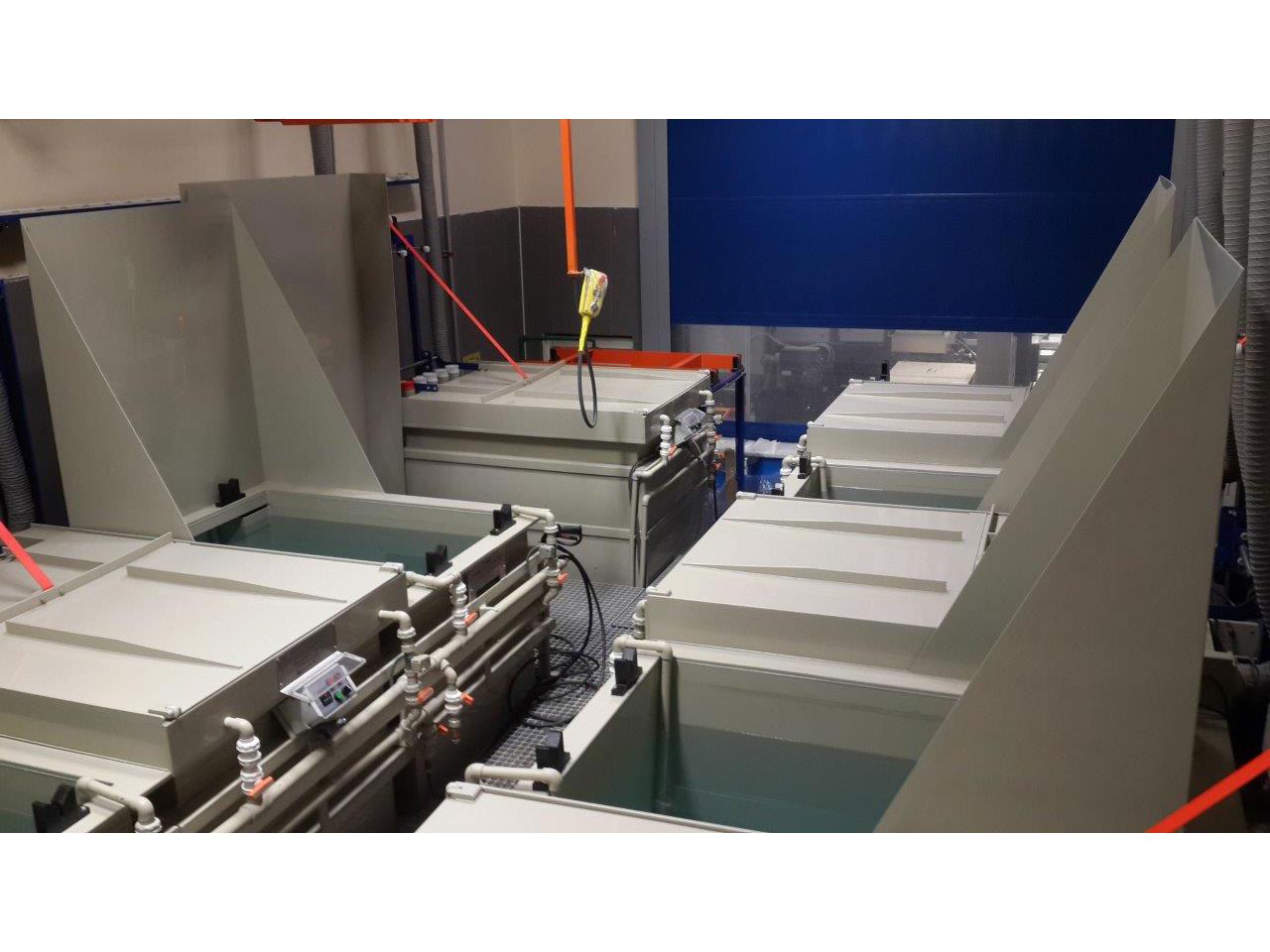

AIRCRAFT FLUSH WASHING AND SURFACE TREATMENT FACILITIES

Titanium Anodized Surface Treatment Plants

Titanium Anodizing System, termed as chemical and water tanks, traveling crane and hoist system, gas cleaning system, chemical neutralization system, heater and control units, direct current generating rectifier and control unit and all other equipment together constitute a functional titanium anodization system.

Titanium Anodizing System;

- Heated Tanks and Tank Equipment

- Rinse / Room Temperature Tanks,

- Air Jet Drying Tank

- Heating and Temperature Control System of Tanks,

- Part Loading and Download Areas,

- Part Transport and Washing Platform,

- Track Transport Straps,

- Part Transport system,

- Parts Transport Baskets,

- Automatic Transport system, (Traveling crane and crane system, Automatic or Manual)

- Floor Grids,

- Rectifier

- Scrubber Unit,

- Workshop Ventilation System,

- Automation and Control unit,

- Overflow Pan / Floor Covering,

- Pressure Washing Cabinet,

- Automatic pH Balancing System

- Deionization System,

- Chemical Loading System,

- Sselpantin cooler and chiller cooler

- Wire Protection and Guardrails,

The Titanium Anodizing System generally consists of the above components and their sub-components: